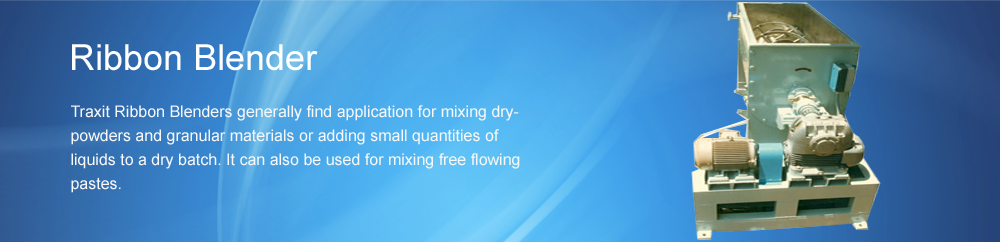

Ribbon Blender

Generally used for blending dry powders or with small quantities of liquid additives. With proper additional features can be as an effective drier also. Capacity - (10 to 10,000 Liters).

Generally used for blending dry powders or with small quantities of liquid additives. With proper additional features can be as an effective drier also. Capacity - (10 to 10,000 Liters).

Traxit Ribbon Blenders generally find application for mixing drypowders and granular materials or adding small quantities of liquids to a dry batch. It can also be used for mixing free flowing pastes.

With additional features like providing a jacket on the trough, designing the trough for vacuum compatibility etc., the equipment can be used as an agitated drier and also for reactions.

The mixer basically consists of horizontal trough having "U" cross section. The two ends of the trough are closed by means of flat or knuckled ends which are generally bolted to mating flanges welded to the container.

Along horizontal axis of the trough runs a shaft which could be made of Solid Bar or Hollow Pipe based on the application. This shaft is held in position by antifriction bearings housed in bearing housings supported on the end plates. On the shaft at various intervals are mounted radial rods which support two sets of Helical Ribbon Mixing Elements.

The two sets of mixing elements are basically the outer and the inner which run along the length of the trough. The outer mixing element runs close to the trough wall where as the inner mixing element runs in between the trough wall and the central shaft. Both the outer and inner mixing elements move the product being processed in the opposite directions along the length of the container, thereby giving intense and homogenous mixing.

The mixer can be adapted for centre or end discharge as dictated by the installation requirement. With increased L/D ratio of the trough and based on the application the mixer could also be used as a continuous mixer.

Ribbon Mixers can be supplied from laboratory sizes of 10 liters to production models of 10,000 liters.

Our Products

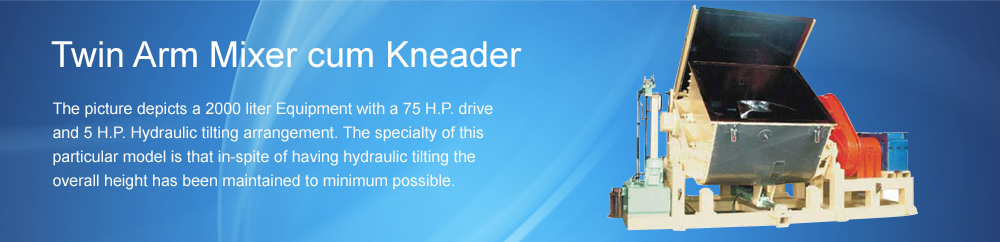

- Twin Arm Mixer cum Kneader

- Tailor Made Planetary Mixers

- Contra Mixer

- Rubber Cutter Dissolver

- Ribbon Blender

- Ploughshare Mixers

- "V" Blender

- Vertical Rotary Air Lock

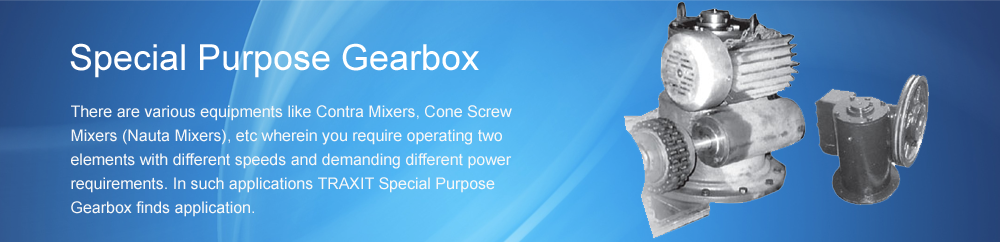

- Special Purpose Gearbox

- TEPL Lube Applicator

- Vertical Ribbon Blender

- Continuous Kneader

- Vacuum Double Planetary Mixer

- Schredder

- Disperser

- Cone Screw Mixer

- MFB Mixer